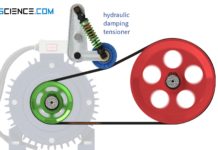

Belt tensioner systems for belt drives

Various belt tensioner systems are used to maintain the tension in the belt. The most important ones are described in more detail below.

https://youtu.be/cZeqLOSA_qE

Why mus belt tension be assured?

The importance of the...

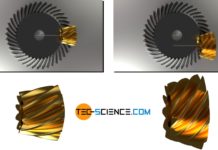

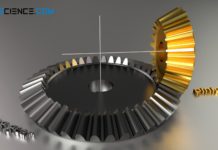

Hypoid gears (screw bevel gears)

With hypoid gears, rotary motions between non-intersecting axes can be realized!

With the bevel gears considered so far, the axes of the ring gear and pinion intersect at a certain point. In...

External and internal toothing of gears

With internal toothing, the center distance to an externally toothed gear can be shortened.

For cylindrical gears, a basic distinction can be made between external gears and internal gears. In the case...

Herringbone gears and double helical gears

Herringbone gears combine the advantage of helical gears (high load capacity) with that of spur gears (no axial forces).

Herringbone gears

In order to combine the advantage of helical gears (higher load capacity...

Helical gears

Helical gears have a lower noise level and can transmit higher torques than spur gears!

When it comes down to reduce noises and transmit high torques, helical gears are often used. With...

Screw gears (crossed helical gears)

Screw gears or crossed helical gears are hyperboloid gears that allow the skew mating of the gear shafts!

With the gears considered so far, the axes of rotation are always parallel when...

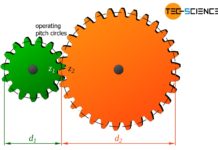

Spur gears (straight-cut gears)

Straight-cut gears (spur gears) are the simplest type of toothing. In a spur gear, up to 3 teeth are in mesh at the same time.

If the teeth of a toothed gearwheel...

Rack (toothed bar)

Racks (toothed bar) allow the rotary motion of a spur gear to be converted into a straight-line motion of the rack.

While only rotary motions occur with conventional cylindrical gears, a rack...

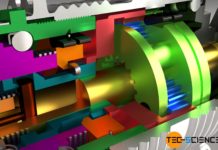

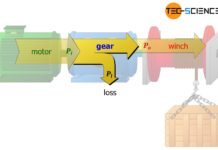

What types of transmissions (gearboxes) are there?

Roughly speaking, gearboxes are divided into four types: gear drives, belt drives, chain drives and friction wheel drive.

Introduction

Transmission are available in many different types, depending on the application, e.g. as gear...

What is a transmission (gearbox) and what is it used for?

Transmissions control the power supplied in favor of a high velocity (rotational speed) or in favor of a high force (torque)!

Where are gearboxes used?

In mechanical engineering there are many technical systems,...

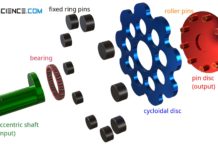

How does a cycloidal drive work?

In this article, you will learn more about the design, the advantages and disadvantages of a cycloidal drive and its application.

https://youtu.be/OguhMDiTqY4

Operating principle

The animation below shows the structure and operating principle of...

Construction of the cycloidal disc of a cycloidal drive

Learn more about the design of the cycloidal disc of a cycloidal drive in this article.

https://youtu.be/OguhMDiTqY4

Design of the cycloidal disc

Cycloidal disc with ordinary cycloid

As already explained in the article "Operating principle",...

Lantern pinion as a special case of cycloidal gear

In this article, you can learn more about a lantern pinion as a special case of cycloidal gear.

https://youtu.be/yDFc9prncII

Operating principle

A special case of cycloidal gearing with point tooth form is the so-called...

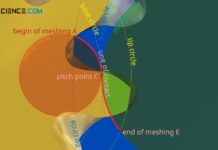

Meshing of cycloidal gears

In this article, learn more about the meshing of the teeth of cycloidal gears.

https://youtu.be/0qiKLyTbS9M

Line of action

The figure below shows the meshing of two cycloidal gears. The dash dotted pitch circles are...

Construction and design of cycloidal gears

The shape of the flank of a cycloidal gear corresponds to a cycloid constructed by rolling a rolling circle on a base circle.

https://youtu.be/0qiKLyTbS9M

Construction of a cycloid

The shape of the flank of...

What is a roots type blower and how does it work?

In this article, learn more about the design and operation of a roots type blower and its application as a supercharger.

https://youtu.be/2rSs-DoOEsg

Operating principle

The animation below shows the operating principle of a Roots-type...

Undercut of gears

Undercut occurs when the number of teeth of a gear is too small. An undercut leads to a weakening of the strength of the tooth!

https://youtu.be/bol1U0BHcew

Undercut

Undercut due to manufacturing process

The animation...

Rack

In this article, learn more about the meshing of the teeth of a gear with the teeth of a rack.

https://youtu.be/g4USx2hj3eU

Introduction

The fundamentals when two gears are meshing have already been explained in...

Engaging of involute gears (meshing)

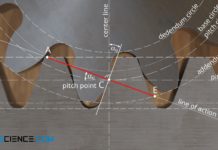

The points of contact of two meshing tooth flanks describe a straight line for involute gears (line of action or line of engagement).

https://youtu.be/lMmWsbdTDng

Line of action

Due to the special design of the...

Calculation of involute gears

https://youtu.be/wsKFVU3X8I8

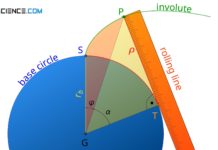

Involute function

For the calculation of involute gears, the involute tooth flank must first be described mathematically. The figure below shows the involute belonging to the base circle with the radius rb....

Gear cutting (gear manufacturing)

Learn more about the different manufacturing processes for cutting involute gears in this article.

Gear hobbing

Involute gears are often manufactured by hobbing. The cutting edges of a hob are straight-flanked and wrap...

Profile shift of involute gears

In the case of a profile shift, the reference profile of the gear is shifted outwards during the manufacturing process in order to positively influence the meshing.

https://youtu.be/RgMSsQApYIk

Introduction

In the article Undercut of...

Construction and design of involute gears

Involute toothing is often used in mechanical engineering for gears, as it offers favorable meshing and is easy to produce.

https://youtu.be/99Msd8sSF8Y

Introduction

In mechanical engineering, the involute is used almost exclusively as a tooth...

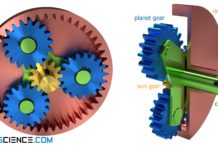

How does a differential gear work?

Learn more about the design, function and application of a differential gear and the differential lock in this article.

https://youtu.be/HY3ZnjZtrQw

Why does a car need a differential gear?

In automobiles, the wheels are usually...

How does a three-speed gear hub work?

Learn more about the structure and function of the planetary gear in a three-speed gear hub in this article.

https://youtu.be/8R3xzAdxYIc

Assembly and function

The figure below schematically shows the assembled components of a three-speed...

Derivation of Willis equation (fundamental equation of planetary gears)

The Willis equation describes the motion of the individual gears of a planetary gearbox (epicyclic gear).

https://youtu.be/oXD9uJb_TOg

Superposition of motions

The change in speed of planetary gearboxes are no longer as easy to understand...

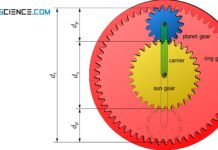

How does a planetary gear work?

A planetary gear is an epicyclic gear in which several gears (planet gears) mesh with a central gear (sun gear).

https://youtu.be/cKjWcUvZuhM

Stationary gearbox

So-called stationary gearboxes are characterised by the fact that the gear wheels...

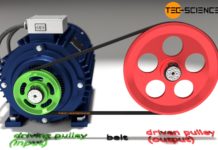

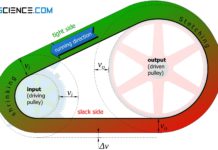

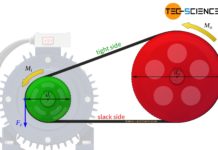

How does a belt drive work?

In belt drives, the power transmission between the driving pulley and the driven pulley is usually force-locked by flexible belts.

https://youtu.be/cZeqLOSA_qE

Introduction

In belt drives, power is transmitted between at least two pulleys by...

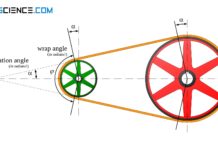

Calculation of the belt length for belt drives

Learn in this article how to calculate the length of belts for belt drives.

https://youtu.be/jaTPaKUVCPk

For the construction of belt drives it is necessary to determine both the wrap angle and the belt...

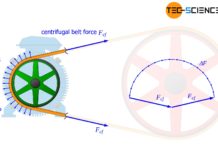

Centrifugal forces in the belt of a belt drive

At high speeds, the centrifugal forces acting on the belt reduce the contact pressure and thus the maximum transmittable circumferential force.

https://youtu.be/nh7xdgnsjys

Formation of centrifugal forces

With a belt drive in a resting state,...

Maximum belt stress in belt drives

In this article, learn more about the maximum belt stress, which must not be exceeded, otherwise the belt will be damaged.

https://youtu.be/hUxWhqKFX2k

Introduction

In general, the forces acting in the belt must not exceed...

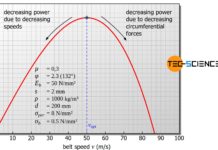

Optimum belt speed for belt drives

At a certain optimum belt speed, a belt drive can transmit the maximum possible power.

https://youtu.be/hUxWhqKFX2k

Introduction

In the article Mechanical power it was shown that an object that is moved by a force...

Calculation of the bearing force for belt drives

Learn more about calculating the bearing force of belt drives at a given preload in this article.

https://youtu.be/jaTPaKUVCPk

Calculation of bearing force

The forces acting in the belt press the belt onto the pulley...

Slippage of the belt in belt drives

The relative motion on the pulleys, which is always present due to the elasticity of the belt, is called elastic slip!

https://youtu.be/QROzu69Tpb4

Elastic slip

When the belt rotates around the pulleys, it is exposed...

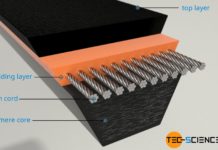

Types of belts for belt drives

In this article, learn more about the different types of belts and their application, as well as the respective advantages and disadvantages.

https://youtu.be/m7bJFHiBKa8

Flat belts

The simplest type of belt is the flat belt....

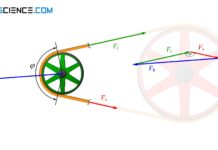

Power transmission of a belt drive

In this article, learn more about the power transmission in belt drives and the necessary pretensioning force.

https://www.youtube.com/watch?v=_My7Kk2MN_0

Circumferential force in the belt

In belt drives, forces are transmitted from the input pulley to...

Basics of power transmission in belt drives

The basis of power transmission in the belt drive is the belt friction equation according to Euler and Eytelwein (rope friction equation).

https://www.youtube.com/watch?v=_My7Kk2MN_0

Forces acting on a fixed pulley

In the article How does...

Bevel gears

In bevel gears, the axes of the gears are at right angles to each other. Bevel gears are used to change the spatial direction of rotation.

Introduction

In contrast to cylindrical gears, where...

Worms and worm gears

With a worm gear, high loads can be transmitted at a high transmission ratio.

Operating principle

A special design of the gear wheel is the so-called worm. In this case, the tooth winds...

Overview of gear types

Depending on the shape of the gears and the type of toothing, gears can be classified as spur gears, bevel gears and worms or worm gears.

The figure below shows a selection...

Lubrication of gears (transmissions)

Gears must be lubricated due to the high stress (friction) when meshing with another gear.

Introduction

Gear wheels of transmissions are subject to wear due to sliding processes on the flanks. Therefore, the...

What is a gear stage?

A gear stage is a wheel pairing within a gearbox at which the speed or torque changes! Learn more about gear stages in this article.

Definition

The figure below schematically shows a toothed...

Mechanical power

The mechanical power is determined by the force and speed or by the torque and rotational speed.

Introduction

The term power (in the physical sense) plays an important role in transmissions, since they have...

How does a gearbox (transmission) work?

The conversion of speed and torque takes place in gearboxes through the arrangement of gears or pulleys of different sizes.

Conversion of speed

As explained in the article What is a transmission...