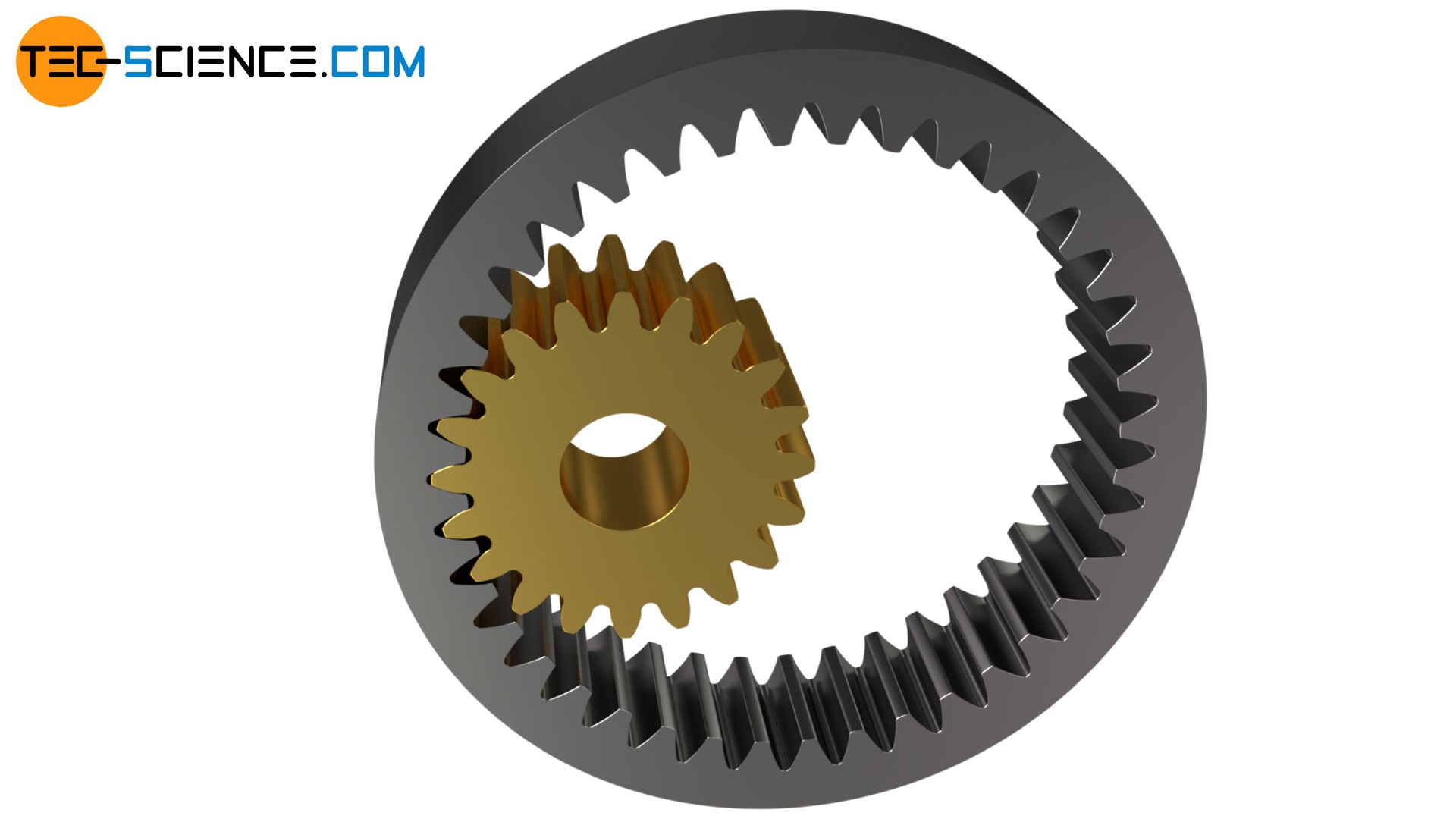

With internal toothing, the center distance to an externally toothed gear can be shortened.

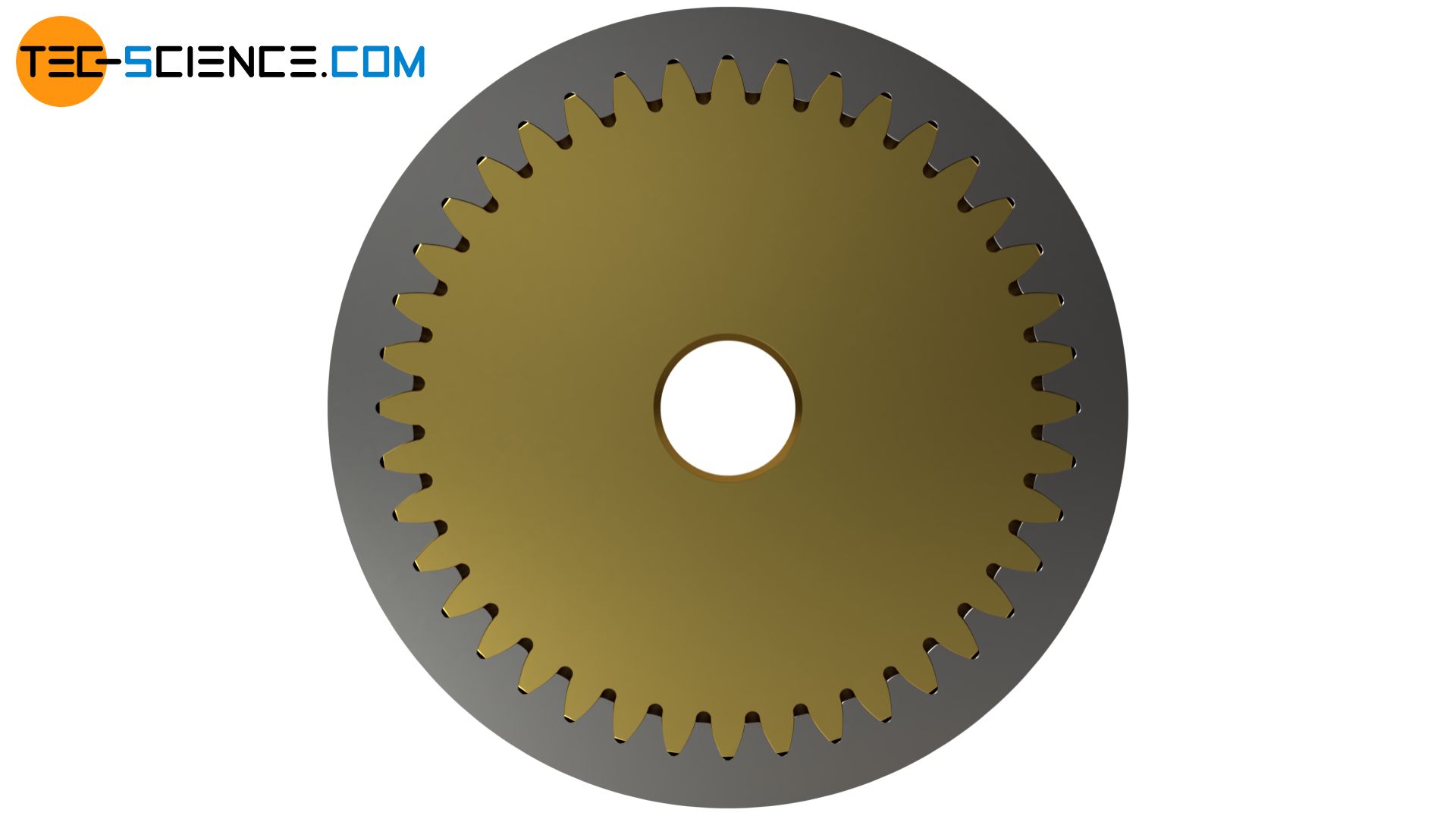

For cylindrical gears, a basic distinction can be made between external gears and internal gears. In the case of external toothing, the teeth are directed outwards on the circumference. In the case of internal gears, the teeth are directed inwards. An internal gear wheel is sometimes simply called a ring gear (although a ring gear can also have an external toothing!).

While the direction of rotation changes when two externally toothed gears are used, the sense of rotation remains the same when pairing with a internal gear. In addition, the centre distance can be shortened by using a ring gear with internal toothing instead of external toothing (with maintaining the transmission ratio). This makes a space-saving gear design possible. Under certain circumstances, internally toothed gears can also offer better protection against dirt due to the internal teeth, if the gear unit has been designed accordingly.

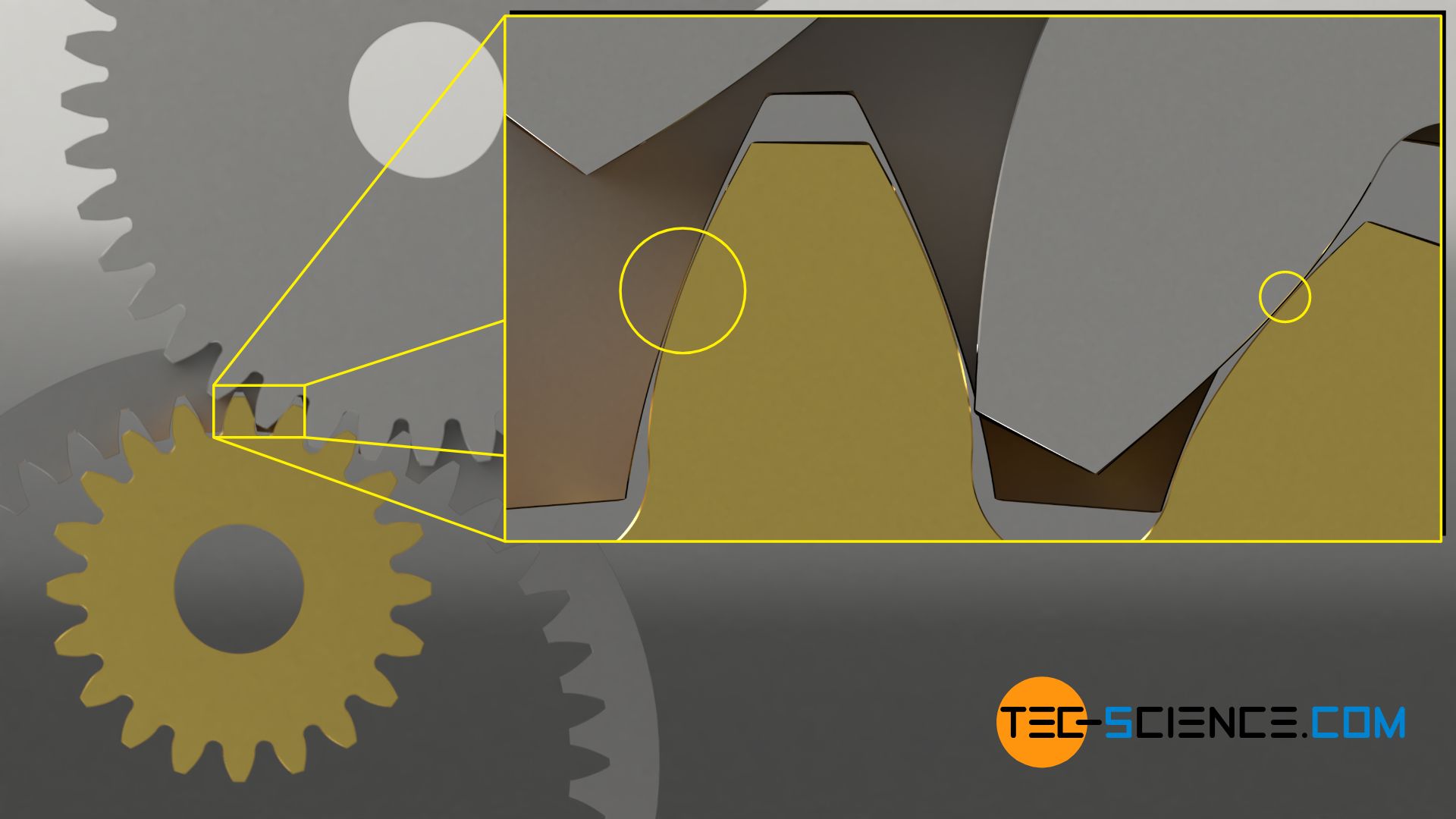

The counterpart of the tooth flank profile of an external gear corresponds in principle to the tooth flank profile of an internally toothed gear. Thus the tooth profile of an external toothing is always convex, i.e. they have an outwardly curved shape (external curvature). With internal toothing, however, the tooth profile is concave, i.e. they are arched inwards (internal curvature).

When two external gears are meshing, a relatively narrow contact surface results due to the purely convex pairing of the tooth flanks. This in turn leads to a high tooth load (also called Hertzian contact stress). Therefore, the wear of the gears and tooth flanks is very high.

If, however, an externally toothed gear is paired with an internally toothed gear, the result is a convex/concave-flank pairing. The contact surfaces “nestle” up against each other, so to speak. This results in a larger contact area, which in turn results in lower tooth load. This reduces the wear of the gears. Conversely, this means that higher torques can be transmitted with the same wear with internal toothing than with the pairing of two externally toothed gears.

Even though internal gears offer many advantages compared to external gears, internal toothing is limited to a few special cases due to the relatively complex and thus expensive production. Internal gearing is used, for example, in planetary gears (epicyclic gears).