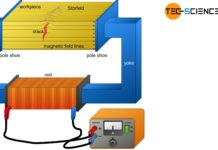

Magnetic particle inspection (MPI)

With magnetic particle inspection (MPI), surface defects such as cracks of ferromagnetic components are made visible.

Introduction

Like the dye penetrant inspection, magnetic particle inspection is also a method for examining surface defects...

Dye penetrant inspection (DPI)

With Dye penetrant inspection, cracks on the surface of components can be made visible in a non-destructive manner.

The dye penetrant inspection (or liquid penetrate inspection) can be used to visualize surface...

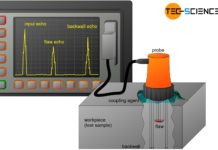

Ultrasonic testing (UT)

Ultrasonic testing uses sound waves to non-destructively inspect a component for flaws.

Introduction

Ultrasonic testing is a non-destructive testing technique because the workpieces or components to be tested are not damaged during the...

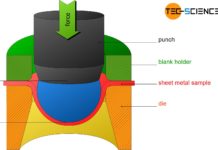

Cupping test

In the cupping test according to Erichsen, the deep drawing behavior of a metal sheet is examined.

Sheets for deep-drawing applications must have very good cold formability, i.e. they must be able...

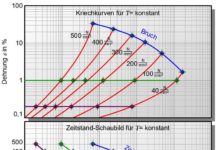

Stress-relaxation test

The relaxation strength indicates for a certain temperature to which value the stress falls at a given strain after a certain time!

In the creep rupture test, material samples are subjected to...

Stress rupture test (creep rupture test)

The creep rupture test (stress rupture test) is used to measure the strength of materials that are subjected to constant stress at elevated temperatures.

Creep

If components are subjected to a constant tensile...

Fatigue test

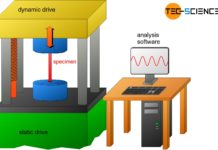

The fatigue test provides information about the strength of a material under continuously changing stress (dynamic load).

https://www.youtube.com/watch?v=V2FItB2m4lk

Introduction

The intensity of the stress increases slowly but steadily in the tensile, compression and flexural...

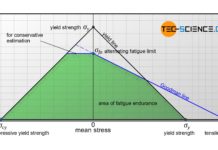

Fatigue limit diagram according to Haigh and Smith

Fatigue limit diagrams according to Haigh or Smith show the maximum yieldable stress amplitude as a function of the mean stress.

https://www.youtube.com/watch?v=pMUbK2DTJRs

Fatigue limit diagrams

Although the Wöhler curve is suitable for the evaluation...

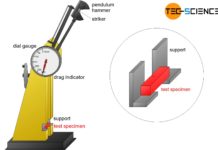

Charpy impact test

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures!

https://www.youtube.com/watch?v=blECIlqda2Y

Introduction

The elongation at break and reduction in area obtained by the...

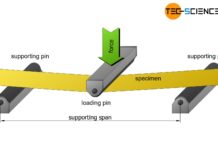

Bending flexural test

In a bending flexural test, a standardized specimen is bent under uniaxial bending stress until plastic deformation or fracture occurs!

https://www.youtube.com/watch?v=B-caaAtTsDk

Test setup

In the bending flexural test, a specimen is loaded under uniaxial...

Compression test

In the compression test, a standardized specimen is loaded under compressive stress until it breaks or until a first crack appears.

The testing of materials under compressive stress is carried out in...

Tensile test

The tensile test is used to determine the strength (yield point, ultimate tensile strength) and toughness (elongation at break) of a material!

https://www.youtube.com/watch?v=nOdcE2pJx2A

Setup

The tensile test is one of the most important testing...

Destructive material testing & non-destructive testing (NDT)

In destructive materials testing, the material is damaged; in non-destructive materials testing, the workpiece is left undamaged.

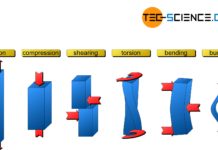

Materials such as steels generally have to withstand a wide variety of loads. The different...