Screw gears (crossed helical gears)

Screw gears or crossed helical gears are hyperboloid gears that allow the skew mating of the gear shafts!

https://youtu.be/9UXIYhE8z_s

With the gears considered so far, the axes of rotation are always parallel when...

Spur gears (straight-cut gears)

Straight-cut gears (spur gears) are the simplest type of toothing. In a spur gear, up to 3 teeth are in mesh at the same time.

https://youtu.be/iYZR8oAr0cY

If the teeth of a toothed gearwheel...

Rack (toothed bar)

Racks (toothed bar) allow the rotary motion of a spur gear to be converted into a straight-line motion of the rack.

https://youtu.be/iYZR8oAr0cY

While only rotary motions occur with conventional cylindrical gears, a rack...

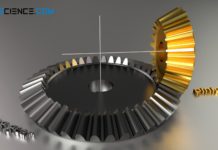

Bevel gears

In bevel gears, the axes of the gears are at right angles to each other. Bevel gears are used to change the spatial direction of rotation.

https://youtu.be/bOowIc54vL4

Introduction

In contrast to cylindrical gears, where...

Worms and worm gears

With a worm gear, high loads can be transmitted at a high transmission ratio.

https://youtu.be/eNL3aAVhD9M

Operating principle

A special design of the gear wheel is the so-called worm. In this case, the tooth winds...

Overview of gear types

Depending on the shape of the gears and the type of toothing, gears can be classified as spur gears, bevel gears and worms or worm gears.

https://youtu.be/iYZR8oAr0cY

The figure below shows a selection...