With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched!

Case hardening

The toughness (ductility) of steels increases with decreasing carbon content, as then less brittle cementite is found in the microstructure. If components are to be very tough, they must inevitably be relatively low in carbon. At the same time, however, the hardenability of the material decreases due to the low carbon content, since the forced-dissolved carbon in the lattice in particular leads to the necessary formation of martensite. As a guideline, the carbon content should be at least 0.3 % for hardening. However, components such as toothed wheels must combine both contradictory properties:

- low carbon content in the core for high toughness (absorption of dynamic loads) and

- high carbon content on he surface for a hardenability of the surface layer (increase of wear resistance).

For such applications case hardening is suitable, which is generally structured as follows:

- carburisation

- cooling (not required for direct hardening)

- hardening (quenching & tempering)

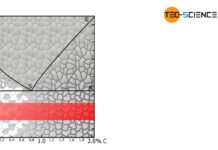

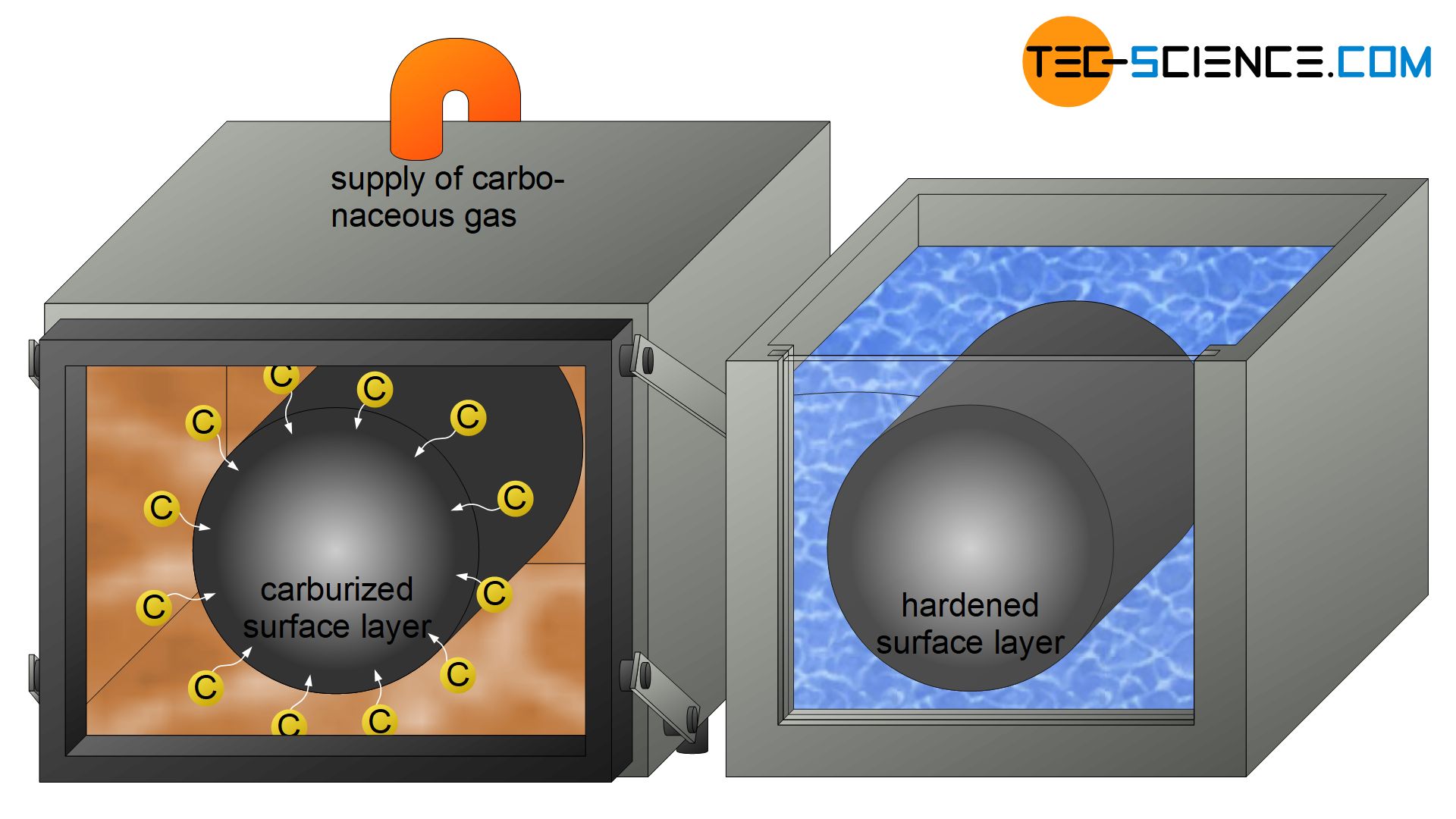

In case hardening, a low-carbon steel (case hardening steel) with a maximum of 0.2 % carbon is first exposed to a carbon-containing environment. In the early days, the steel was practically placed in a “case” of glowing coke. The carbon then diffuses into the surface layer, where it leads to an enrichment of the carbon content to a hardenable level of about 0.8 % carbon, while the core remains low in carbon. This carbon accumulation in the surface layer is also called carburisation.

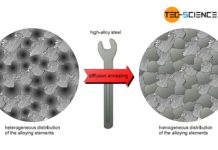

Since only the austenite structure is able to absorb sufficient amounts of carbon, the temperature during carburizing is above 900 °C with a carburizing time of several hours. Carburizing depths of 0.1 to about 5 mm can be economically achieved with this method. Since carburizing is a diffusion-controlled process, the carburization times can be reduced with higher temperatures, but at the same time the risk of coarse grain formation increases.

Carburizing can be carried out in different ways. During gas carburizing, the component is exposed to a carbon-containing atmosphere. This is particularly economical in mass production. Carburisation in salt baths is also possible. In addition, it is possible to carburize workpieces in powdered carbon granulate.

After the surface layer has been carburized to the desired hardenable level, the actual hardening process takes place, whereby the relatively low-carbon core is slightly quenched and tempered. The quenching required for this can be either done

- after a slow cooling from the reheated state (single and double quench hardening) or

- directly from the still hot carburizing state (direct hardening).

After quenching, the hardened components are always tempered and thus obtain their final service properties. Above all, the increase in fatigue strength makes case hardening very interesting for dynamically stressed components such as gears or drive shafts.

With case hardening, low-carbon steels are first enriched with carbon in the surface layer (carburisation) and then quenched! Such components are characterised by their high surface hardness combined with a very tough core (since low-carbon content)!

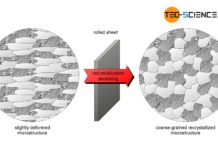

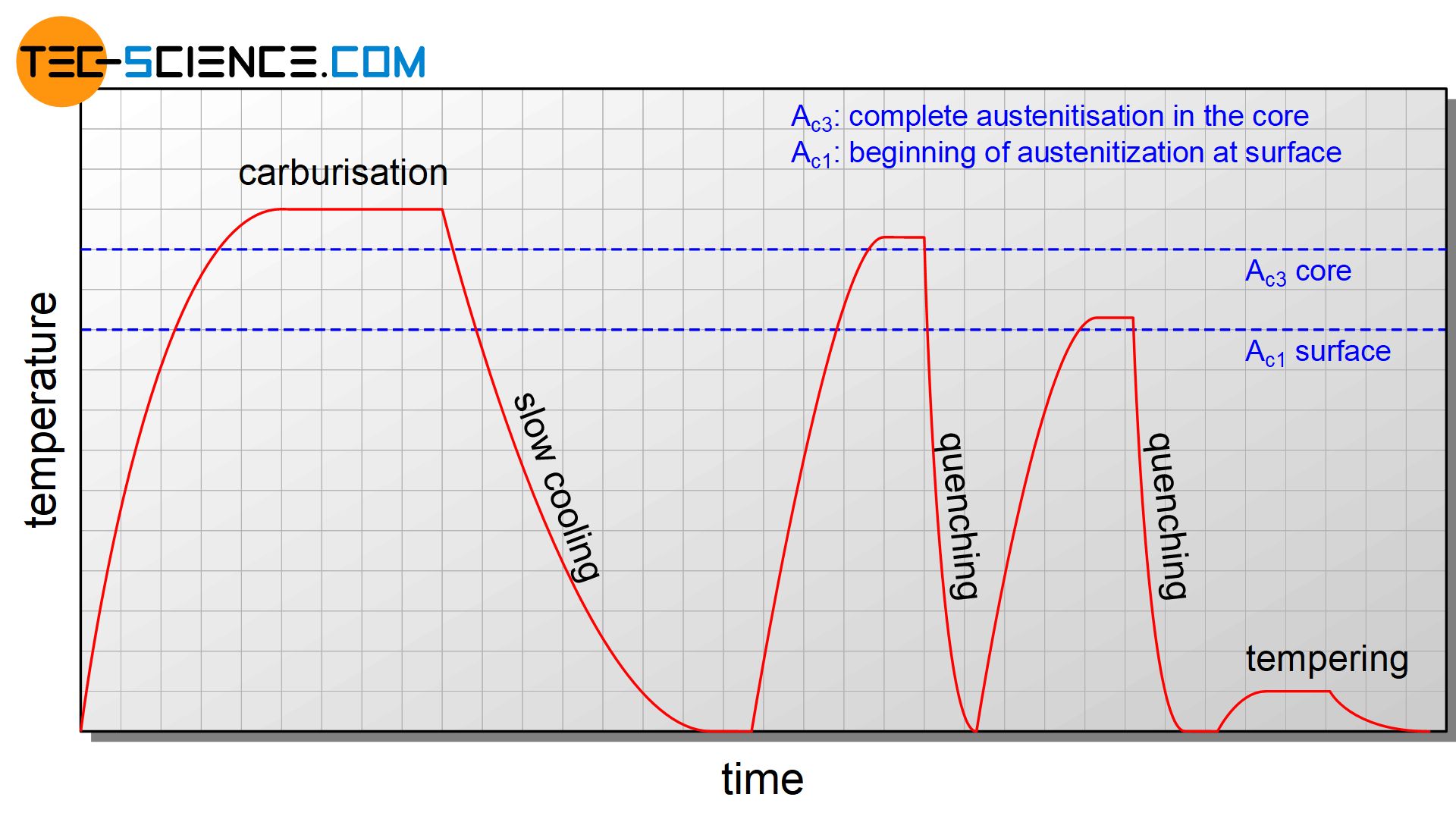

Single-quench hardening

Single quench hardening is a special case hardening process. It is suitable for steels that tend to form coarse grains during carburizing or for components that still require intermediate machining before hardening. In this process, the steel is cooled slowly after carburizing. For the actual hardening process, the steel is then heated again in a separate process step. The \(\gamma\)-\(\alpha\)-transformations cause a recrystallisation effect, which leads to grain refinement of the coarsely grown grains during carburisation.

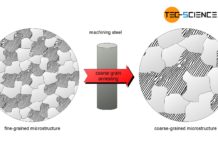

The hardening temperature can be selected so that the austenitisation mainly takes place in the marginal area (due to the carburised surface, the temperature required for complete austenitisation is lower there than in the lower-carbon core area!) This austenitized state at about 750 °C is then quenched to achieve the desired martensite formation in the surface layer.

Due to the relatively low surface hardening temperatures, however, the lower-carbon core is not completely austenitized, so that no completely martensitic core structure is formed after quenching. Residual ferrite is to be expected in the core. In this case, the hardening temperature is preferably adapted to the desired properties of the surface layer in order to achieve optimum surface properties. This is why the process is also referred to as surface hardening or single quench hardening from surface hardening temperature.

In principle, the hardening temperature can also be selected so that the core is specifically austenitized. Due to the lower carbon content, however, higher temperatures of approx. 900 °C are necessary. This so-called core hardening temperature is then used for quenching. However, due to the high temperatures, a coarse needle-like microstructure in the surface layer is to be expected during core hardening. In this case, the temperature control is preferably adapted to the desired core properties in order to achieve optimum core properties. This is why the process is also referred to as core hardening or single quench hardening from core hardening temperature.

Single quench hardening specifically influences the properties of the surface (surface hardening) or the core (core hardening)!

Double-quench hardening

In principle, a combination of core and surface hardening is also possible. After carburizing, the workpiece is first cooled slowly and then reheated to core hardening temperature or cooled to core hardening temperature immediately after carburizing. The material is then quenched to adjust the core properties. Subsequently, the material is reheated to surface hardening temperature and then quenched in order to obtain optimum surface properties. However, due to the permanent change in temperature, the hardness distortion in this double quench hardening is relatively high.

With double quench hardening, first the desired properties of the core are adapted (core hardening) and then those of the surface (surface hardening)!

The reheating during single and double quench hardening makes these processes relatively energy- and time-intensive and therefore expensive. The advantage, however, is the grain refinement that occurs through the \(\gamma\)-\(\alpha\)-transformations. However, for steels that do not tend to form coarse grains in the first place (e.g. chrome-molybdenum steels), it is therefore economically more sensible to quench the steel directly after carburizing from the already heated state. Fine grain steels are also suitable for this direct hardening process, which is explained in more detail in the following section.

Single and double quench hardening is usually carried out on steels with a tendency to coarse grain formation, as a recrystallisation effect occurs during the \(\gamma\)-\(\alpha\)-transformations!

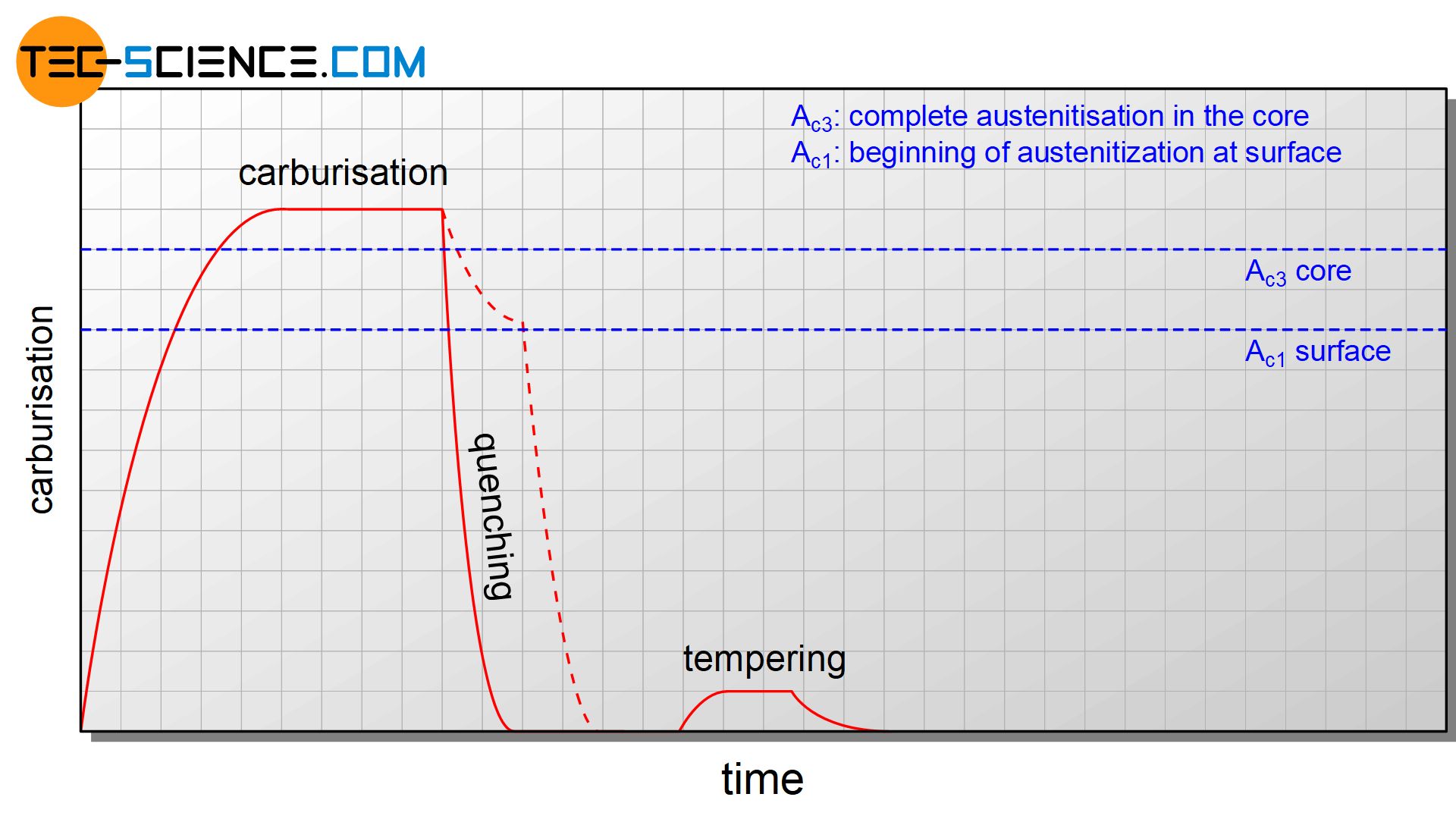

Direct hardening

Direct hardening is a special case hardening process. In this process, the steel is quenched directly after carburizing from the already heated state. Compared to single and double quench hardening, direct hardening is less time-consuming and energy-intensive and therefore less expensive, since reheating is not necessary. Direct hardening is always suitable when steels do not tend to coarse grain formation and therefore single or double quench hardening is not necessary.

Depending on the temperature in the surface layer or in the core, either the surface layer properties or the core properties of the workpiece can be specifically influenced during quenching. For this purpose, the component is either cooled down to core hardening temperature after carburizing or brought to case hardening temperature. After quenching, tempering takes place again at low temperatures.

In direct hardening, the heated steel is quenched directly from the carburized state!