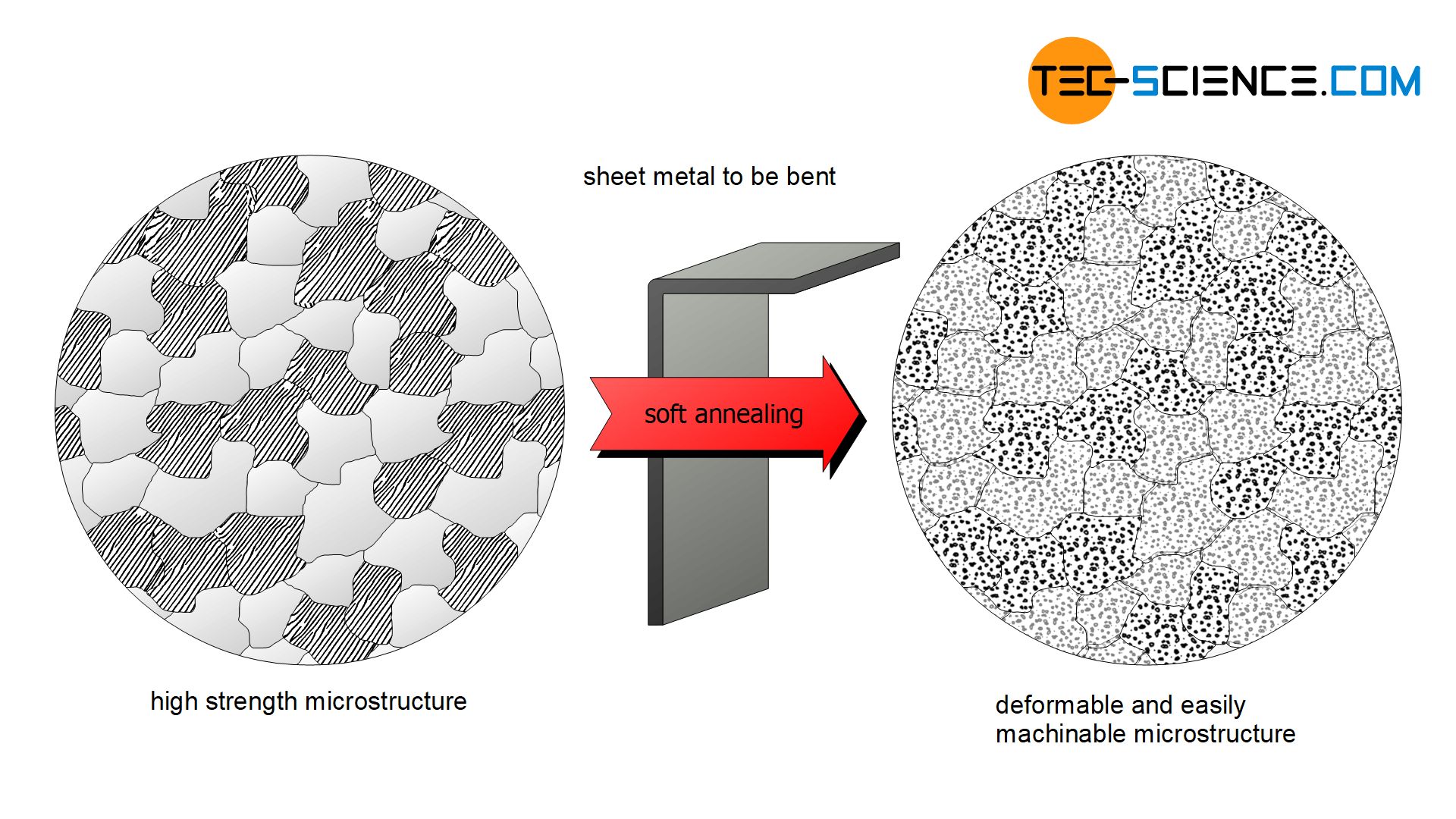

The aim of soft annealing is to improve formability and machinability!

Not every material has to be designed to withstand high mechanical forces. With a curved sheet metal with milled out slots, for example, it is not necessary for the material to be able to absorb high forces. Rather, the focus in the selection of materials is on good formability and machinability of the steel. This plays an important role, especially in automated production with large batch sizes, in order to make production economical.

For this reason, it may be necessary to adapt the microstructure of a steel in such a way that it can be better formed and/or machined. Particularly with regard to formability, it is therefore necessary to produce a correspondingly soft microstructure. This can be achieved by so-called soft annealing.

The aim of soft annealing is to improve formability and machinability!

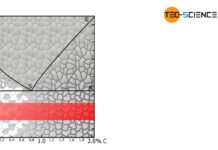

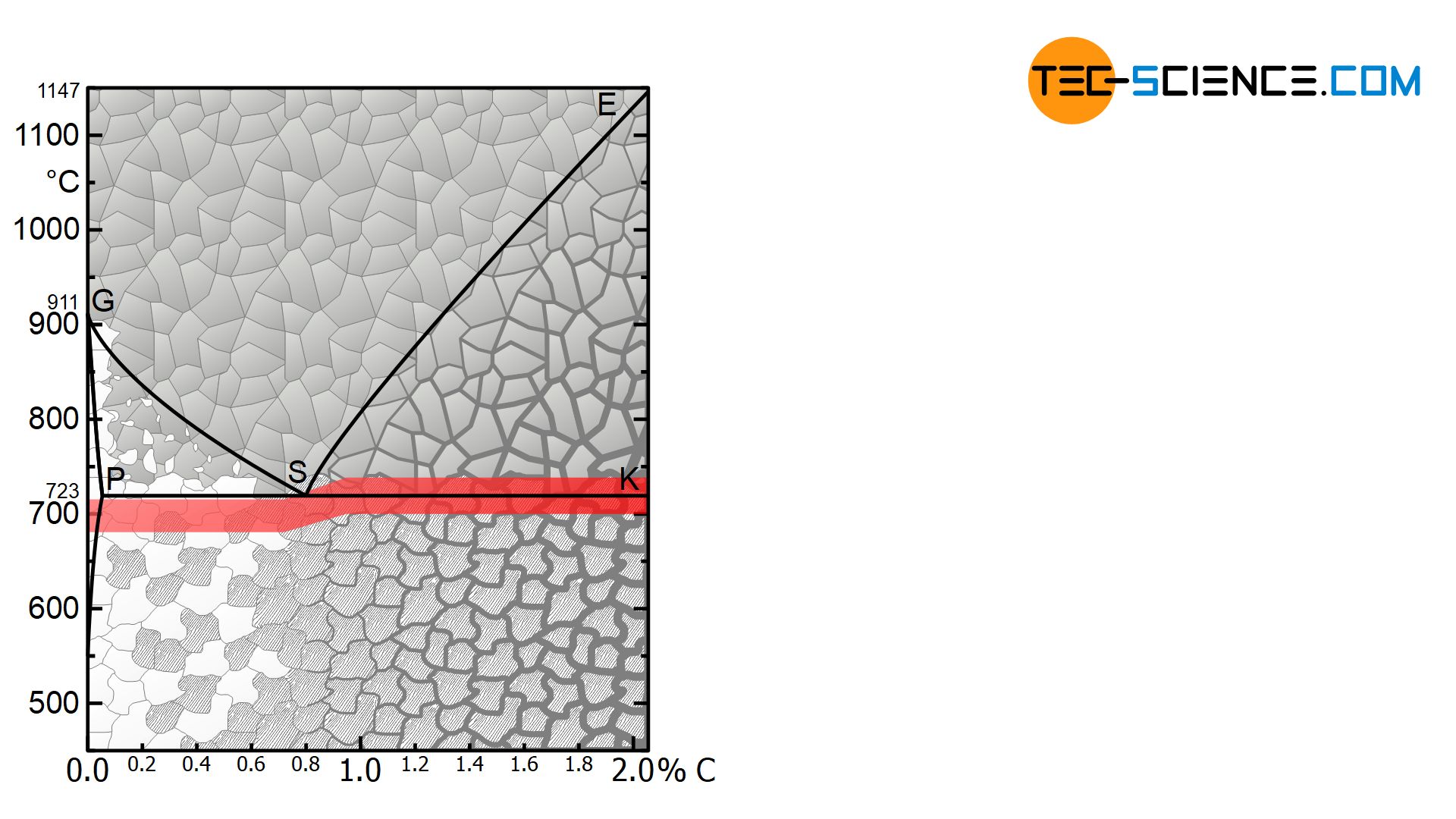

During soft annealing, hypoeutectoid steels are heated to just below the PS-line so that the cementite does not just yet decompose. The lamellar cementite now has enough time to transform through diffusion processes into the thermodynamically more favourable, roundish form. The strip cementite in pearlite transforms into spherical cementite (spheroidal cementite). After the cementite has disintegrated into the round shape, the steel is slowly cooled. In contrast to hypoeutectoid steels, hypereutectoid steels are heated during soft annealing just above or oscillating around the PSK-line.

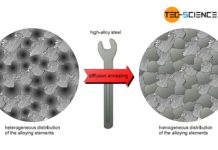

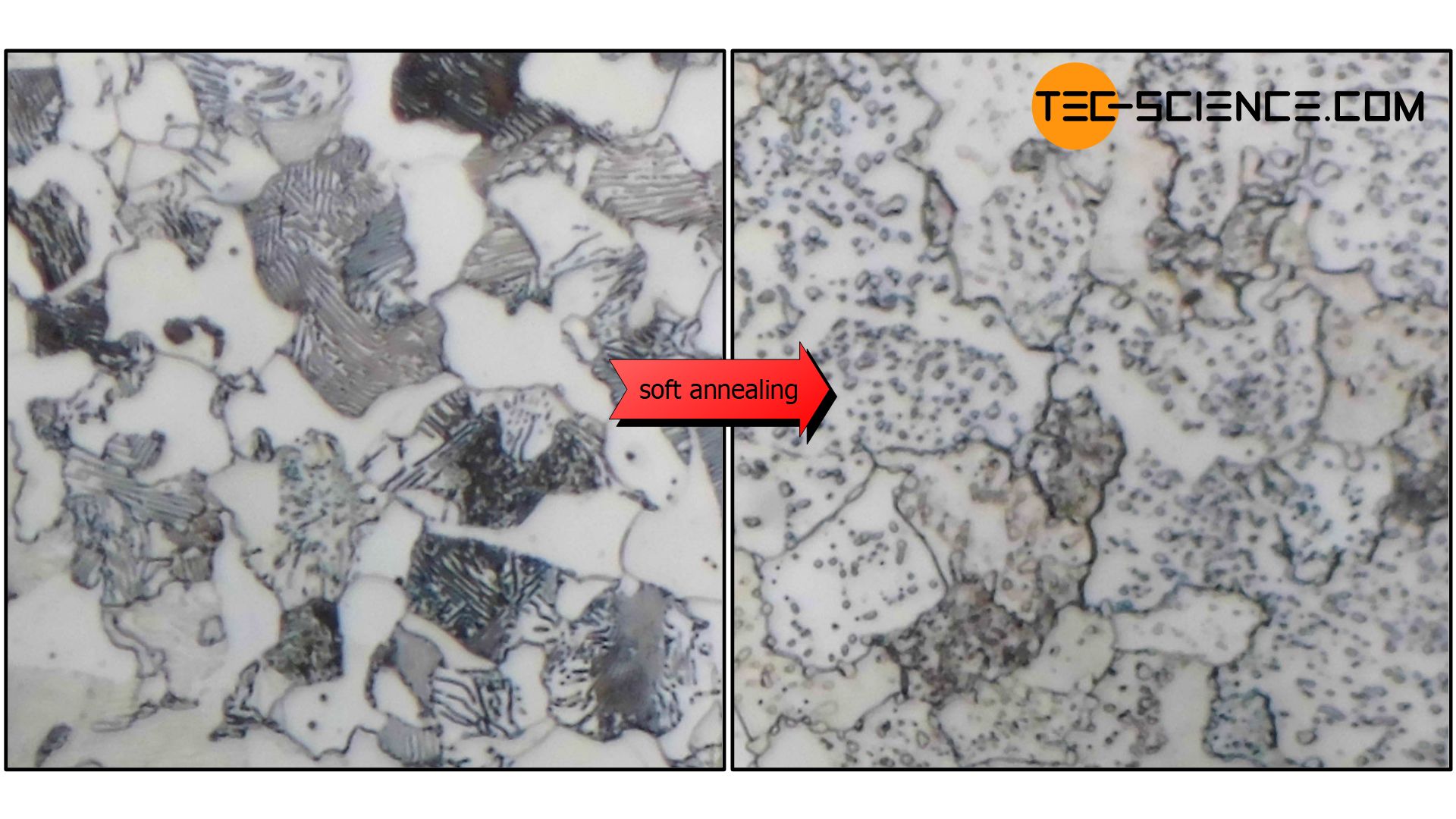

A particularly homogeneous microstructure with finely divided spheroidal cementite can be achieved by hardening the steel before soft annealing. The spherical cementite is then formed from the relatively homogeneous martensite microstructure.

After soft annealing, the steel shows much better formability due to the spherical cementite shape. The cause lies in the facilitated dislocation movement. While the strip-shaped cementite lamellas partially extend completely from one end of the grain to the other, the cementite spheres are only occasionally present in the grain. The dislocation movement is thus less strongly hindered by the spheroidal cementite than with the completely penetrating strip cementite. The deformability increases accordingly, while the hardness decreases.

This facilitates subsequent rolling, bending, deep drawing, etc. due to reduced forming forces. In addition, the spherical cementite achieves better machinability, as the cementite spheres offer less resistance to the tool cutting edge compared to the lamellar cementite form. This increases the durability of the tool accordingly.

Spheroidal cementite improves the machinability of the microstructure compared to lamellar cementite!

The micrograph below shows a soft-annealed steel C45 with the cementite lamellae disintegrating into small roundish spheres.

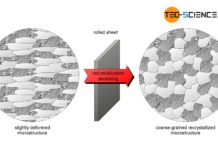

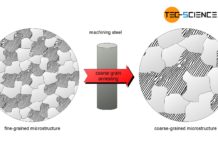

Hypoeutectoid steels with a carbon content below approx. 0.3 % carbon are generally not soft annealed, as these are relatively soft anyway. Although these steels already have good formability, their machinability is unfavourable due to the tendency to form built-up cutting edges at the tool edges. In order to give these low-carbon steels good machinability, the coarse-grain annealing described below can be used as heat treatment.