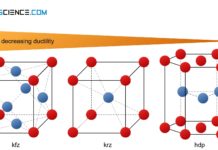

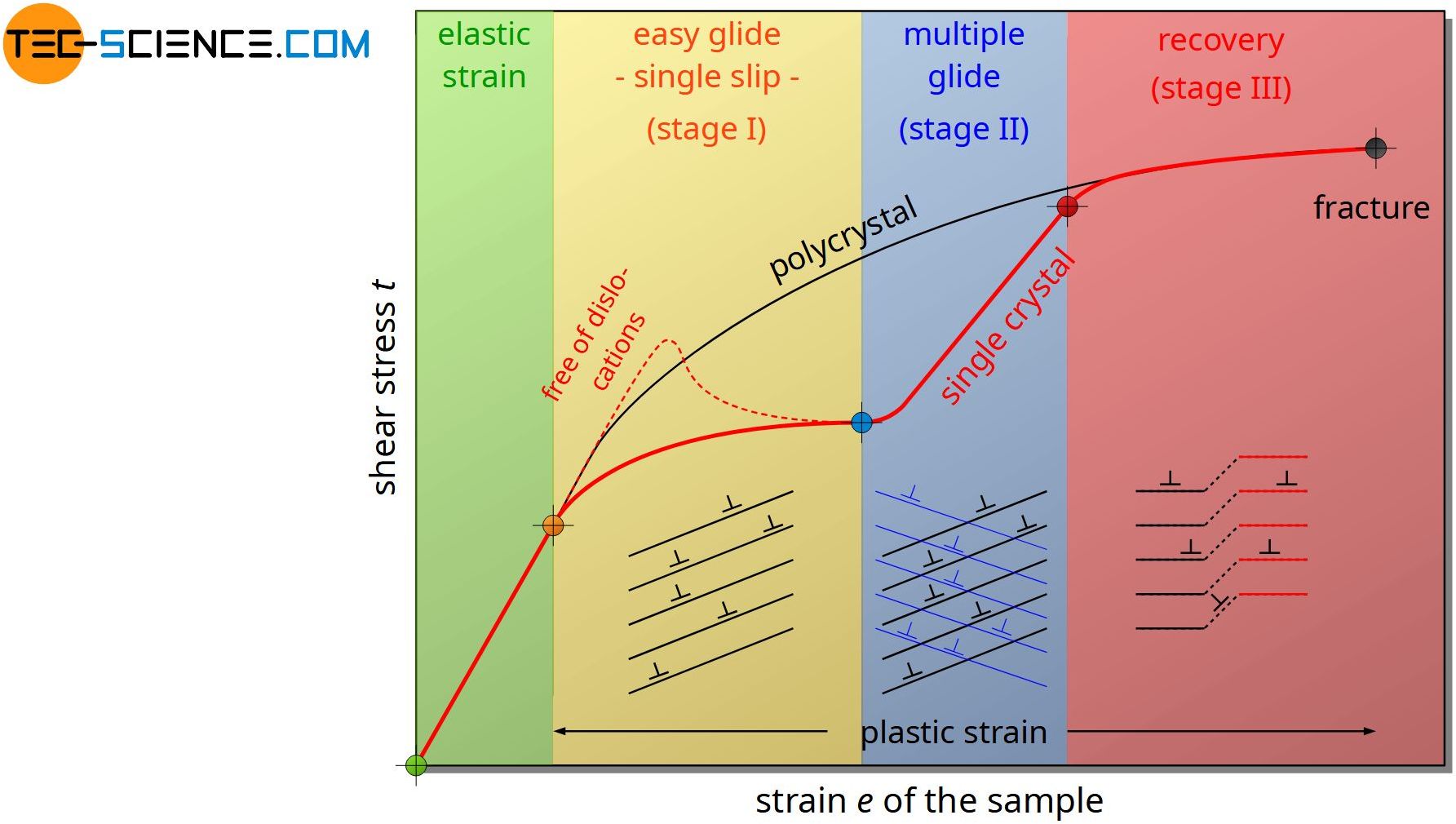

Deformation in single crystals is divided into four stages: elastic, easy glide (single slip), multiple glide and recovery.

Introduction

Even if single crystals are used far less than polycrystals, one can understand very well the processes of deformation. In particular, the stress-strain curve of a single crystal sample will be discussed in more detail below.

Stage 0 – elastic strain

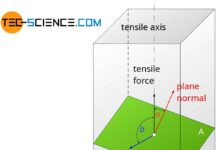

As explained in the article deformation of single crystals, at first the slip plane which is aligned at an angle of about 45° to the tensile axis will be prefarably activated, since in this slip plane the critical resolved shear stress (CRSS) is reached first.

On the other hand, if the stress is below the CRSS, the deformation vanishes completely after removing the external force (reversible, elastic deformation).

If the shear stress value \(\tau\) ist represented in a graph against the strain value \(\epsilon\), one will see at first a linear relationship between both values (stage 0). This linear relationship is also referred to Hooke’s law. Within the straight line in the stress-strain-curve only elastic deformation will occur. This applies only as long as the shear stress does not exceed the CRSS.

If the shear stress is below the CRSS the material will only be exposed to elastic deformation. Shear stress and strain will then show a linear behavior (Hooke’s law)!

Stage I – single gliding

If the single crystal is stretched beyond the elastic strain, then the critical resolved shear stress is exceeded in a favorable oriented slip plane. The dislocations begin to migrate and the irreversible plastic deformation process starts. In order to maintain the deformation process, the dislocations must then only be kept “running”. The deformation process therefore takes place without the need for an excessive increase in tension. The material behaves relatively soft in this state.

In addition, new dislocations are introduced in the material due to the deformation process. Many moving dislocations ultimately mean good ductility, so that the deformation is practically multiplied. Therefore, the curve in the stress-strain diagram becomes increasingly flatter (stage I). Since only one a slip system is active, this stage is also called single gliding or easy gliding.

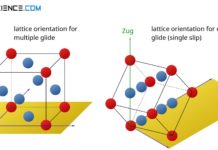

At moderate stresses, only one slip system is active (preferably oriented at 45°). This is also called single gliding or easy gliding!

Note: In extreme cases, the dislocation multiplication even leads to the fact that in dislocation-free single crystals the stress even decreases after starting the plastic deformation process. Because in such a case, dislocations must be generated first to a significant extent under increased force. Only when sufficient dislocations are present, the deformation process can be continued with lower shear stress.

Stage II – multiple gliding

If the deformation process is continued and the stress is therefore further increased, the critical shear stress will eventually be exceeded in other slip planes (which are slightly less favorable).

In addition, due to the deformation of the single crystal, a spatial reorientation of the slip planes will occur, so that previously unfavorably located slip planes can now be displaced into more favorable positions. The movement of dislocations then takes place in several differently oriented slip systems. This is the stage of multiple gliding (stage II).

In the stage of multiple gliding several slip systems are active due to higher stresses!

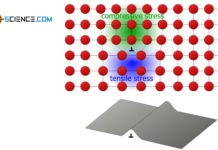

Inevitably, the moving dislocations will meet at the different slip planes and influence each other. Because every dislocation causes compressive and tensile stresses in the immediate vicinity of their dislocation line, which in turn influence other mofing dislocations.

This becomes particularly significant when two dislocations intersect. Energetically, this is possible only with great effort. However, such situations will inevitably occur when several different slip systems become active at the same time. At this stage of multiple gliding, the dislocations therefore hinder each other from moving.

As a result, however, the deformation process is made considerably more difficult, because ultimately a good deformation process is based precisely on the free displacement movement. Thus, now a larger stress is required to further drive the deformation process. At the same time, however, more dislocations are also introduced into the material as a result, which leads to a further increase in the mutual hindrance of the dislocation movement.

It comes in the material to a “dislocation jam”, so to speak. The stress must therefore be greatly increased to ensure further deformation. Stress and strain behave almost linearly in this stage.

If two dislocations are perpendicular to one another on different slip planes, this is also referred to as a forest dislocation. As well as other dislocations, forest dislocations remain in the material after removal of the force. If the deformation process is repeated again, it is mainly these forest dislocations that make the deformation process more difficult from the start. The materiel is now much harder to deform than before. This principle is referred to as work hardening to achieve a strength-increasing effect (also called strain hardening).

Forest dislocations are perpendicular dislocations that block each other! Forest dislocations significantly contribute to strain hardening!

Stage III – crystal recovery

The dislocations that are dammed up or held on crystallographic defects can only be torn loose by larger stresses. The dislocations then spread on other slip planes by diffusion processes. In the case of screw dislocations, this phenomenon is called cross-slipping or, in the case of step dislocations, climbing.

The dislocations thus open up new opportunities to move. Due to the newly gained mobility, the deformation process becomes easier. Therefore, now only a lower increase of stress is needed to further deform the single crystal (stage III). The crystal has, so to speak, “recovered” from the blocking of the dislocation movement, which is why this stage is also referred to as a crystal recovery.

Dislocations can cross-slip oder climb by diffusion processes to other slip planes. The dislocations gain new mobility and the material becomes more ductile (“crystal recovery”).

At some point, however, the atomic cohesion can no longer withstand the stresses in the material. The sample finally breaks.

Note

If the considered monocrystal is spatially aligned in such a manner that under load no slip plane is preferably oriented, the critical shear stress is exceeded simultaneously in several different slip planes. Thus, already at the beginning of the plastic deformation multiple gliding will occur. In this case, the stress-strain curve omits stage I.

Such multiple gliding will generally be present in polycrystalline materials, since the individual crystallites (grains) are randomly oriented. In this way, the stress-strain curve of these materials can be explained, too.