External and internal toothing of gears

With internal toothing, the center distance to an externally toothed gear can be shortened.

https://youtu.be/iYZR8oAr0cY

For cylindrical gears, a basic distinction can be made between external gears and internal gears. In the case...

Herringbone gears and double helical gears

Herringbone gears combine the advantage of helical gears (high load capacity) with that of spur gears (no axial forces).

https://youtu.be/iYZR8oAr0cY

Herringbone gears

In order to combine the advantage of helical gears (higher load capacity...

Spur gears (straight-cut gears)

Straight-cut gears (spur gears) are the simplest type of toothing. In a spur gear, up to 3 teeth are in mesh at the same time.

https://youtu.be/iYZR8oAr0cY

If the teeth of a toothed gearwheel...

Helical gears

Helical gears have a lower noise level and can transmit higher torques than spur gears!

https://youtu.be/iYZR8oAr0cY

When it comes down to reduce noises and transmit high torques, helical gears are often used. With...

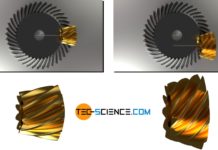

Hypoid gears (screw bevel gears)

With hypoid gears, rotary motions between non-intersecting axes can be realized!

https://youtu.be/9UXIYhE8z_s

With the bevel gears considered so far, the axes of the ring gear and pinion intersect at a certain point. In...

Rack (toothed bar)

Racks (toothed bar) allow the rotary motion of a spur gear to be converted into a straight-line motion of the rack.

https://youtu.be/iYZR8oAr0cY

While only rotary motions occur with conventional cylindrical gears, a rack...