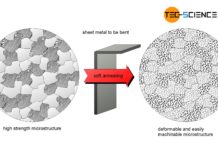

Soft annealing of steel

The aim of soft annealing is to improve formability and machinability!

https://youtu.be/PJ2FKTHAo5s

Not every material has to be designed to withstand high mechanical forces. With a curved sheet metal with milled out slots,...

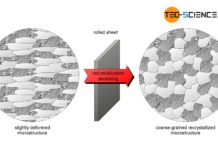

Recrystallization annealing of steel

The aim of recrystallisation annealing is to restore a deformed microstructure to improve its deformability!

https://youtu.be/PJ2FKTHAo5s

The microstructure of rolled, bent or deep-drawn workpieces is strongly deformed by the high forming forces. This...

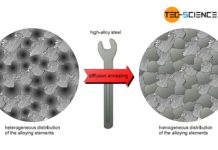

Diffusion annealing of steel

The aim of diffusion annealing is to compensate for concentration differences!

https://youtu.be/PJ2FKTHAo5s

When steels with high alloy concentrations solidify, the alloying elements may not be distributed homogeneously in the microstructure or in the...

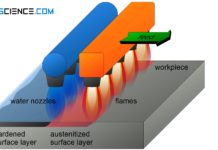

Flame hardening of steel (surface hardening)

Surface hardening is used to produce a hard and wear-resistant surface layer on steel workpieces, while the toughness in the core is largely retained.

https://youtu.be/7UcNNuqKA6U

Introduction

A hard surface layer is essential to increase...

Stress relief annealing of steel

The aim of stress-relief annealing is to release residual stresses!

https://youtu.be/PJ2FKTHAo5s

If a steel is heated or cooled unevenly, internal stresses can arise, also known as residual stresses. Such residual stresses are often...

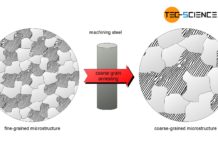

Coarse-grain annealing of steel

The aim of coarse grain annealing is to improve machinability!

https://youtu.be/PJ2FKTHAo5s

In general a coarse-grained steel microstructure is undesirable due to the relatively low toughness and strength values. The only advantage of a...

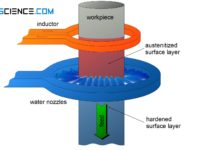

Induction hardening of steel (surface hardening)

With induction hardening, the workpiece is heated by induced eddy currents. The hardening depth is controlled by the frequency of the alternating current!

https://youtu.be/7UcNNuqKA6U

The flames during flame hardening generally lead to a...

Nitriding of steel (surface hardening)

Nitriding is not based on the formation of martensite but on the formation of hard and wear-resistant nitrides on the surface of the workpiece!

https://youtu.be/7UcNNuqKA6U

Surface hardening like flame hardening, induction hardening, laser...

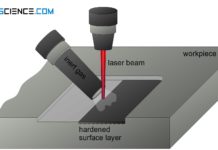

Laser hardening of steel (surface hardening)

With laser hardening, the surface is heated by a laser beam and quenched by heat dissipation in the workpiece (self quenching)!

https://youtu.be/7UcNNuqKA6U

Laser-beam hardening (laser hardening) offers even shorter heating times of the...

Solution annealing of steel

The aim of solution annealing is to dissolve formed precipitates!

https://youtu.be/PJ2FKTHAo5s

During welding or hot forming, microstructural changes occur in the steel due to the influence of heat and uncontrolled cooling. This is...